After a long and successful OEM partnership with Ansys, RBF Morph has two proprietary products featured among the world simulation leader’s offerings: Ansys RBF Morph Fluids and Ansys RBF Morph Structures.

The two simulation tools are based on RBF Morph’s 10+ years of experience with 100+ global customers, including some of the top players and OEMs in the automotive and aerospace industries.

Radial Basis Functions (RBF) are considered by the scientific community one of the best mathematical tools for mesh morphing, a technique used to modify or deform a geometric mesh while maintaining its overall structure and characteristics. This approach is crucial in developing safety-critical complex applications in the automotive, aerospace, and medical industries. Thanks to mesh morphing, companies can substantially reduce computational time while performing highly automated design optimization analysis, increasing products’ reliability and performance while cutting costs, delivery time and environmental impact.

Today’s products represent cutting-edge mesh morphing technology that can help companies optimize their products and achieve optimal efficiency within the Ansys simulation platform.

Ansys RBF Morph Fluids is an add-on that allows for automated shape optimization studies entirely within Ansys Fluent, leveraging morphing of the existing mesh. This new approach takes advantage of Ansys Fluent’s CFD technology and overcomes the limits of the mainstream methods by implementing dedicated morphing routines directly into Ansys Fluent’s CFD code.

Ansys RBF Morph Structures is an ACT extension that allows for automated shape optimization studies entirely within Ansys Mechanical and Ansys Workbench by morphing the existing mesh.

The main advantages of RBF mesh morphing are:

- The capability of handling any mesh, making it very flexible and usable in any situation

- Fully integrated with Ansys CAE solvers, with a seamless user experience

- No need for re-meshing and highly parallelizable to significantly cut computational time

- Robust process, used for decades by top players in the industry with proven cost cutting and improved performance results, up to a 5x factor

“Thanks to our partnership with RBF Morph, Ansys can offer users an advanced solution for mesh morphing that integrates seamlessly into the Ansys platform,” said Prith Banerjee, Chief Technology Officer at Ansys. “These state-of-the-art tools are able to address the most challenging applications in any industry using the predictive power of simulation.”

“We have been proudly serving Ansys users since 2009,” said Marco Evangelos Biancolini, RBF Morph’s Founder and CTO. “We started with CFD, an Add-On for Fluent and since then we gradually expanded our integration within the Ansys product family: Ansys Mechanical, Design Explorer, Twin Builder, optiSLang and LS-DYNA. Today we have two solutions fully integrated with Ansys Fluids and Ansys Structures to enable the best multi-physics optimization and digital twin creation. The expanded OEM arrangement marks a new chapter in our cooperation with Ansys and will allow to jointly replicate the successes we have been bringing to 100+ Ansys customers.”

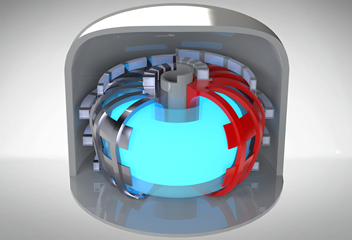

Image 1 (left): Nuclear Fusion: An analysis of a tokamak nuclear-fusion reactor, which confines plasma at very high temperatures using superconducting magnets. The engineering challenge lies in withstanding the huge electromagnetic loads acting on the coils. A stress reduction of 36% can be achieved by reshaping the TF coils, using Ansys Mechanical, Ansys RBF Morph Structures, and optiSLang. The new design is shown in red.

Image 2 (center): Digital Twin: This medical digital twin of the human airways aims to provide patient-specific care and optimal drug delivery. Ansys Fluent, Ansys RBF Morph Fluids, and Twin Builder are used in combination to generate thousands of patient simulations. The image represents the baseline mesh of an average patient as a transparent gray surface. The patient-specific morphed version with CFD results is color-shaded.

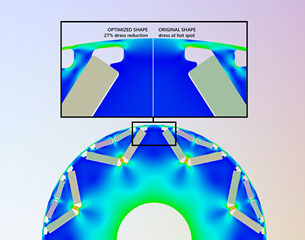

Image 3 (right): Electric Engine: Optimal performance of electric motors is required to ensure both maximum power efficiency and structural reliability in transportation applications. Here, Ansys Maxwell, Ansys Mechanical, and Ansys RBF Morph Structures are being applied to optimize performance and durability. The parameter-free shape optimizer of RBF Morph allows for the reshaping of the most stressed pocket, resulting in a 27% reduction in stress.